Solvent Extraction Crud Industry

Flottweg decanters and Tricanter® machines are used in the following process industry applications:

- Processing lubricating oil

- Processing used oil

- Processing extraction agents

- Processing cooling lubricants

- Processing fuel oil

- Processing diesel oil

- Processing crud for metal extraction

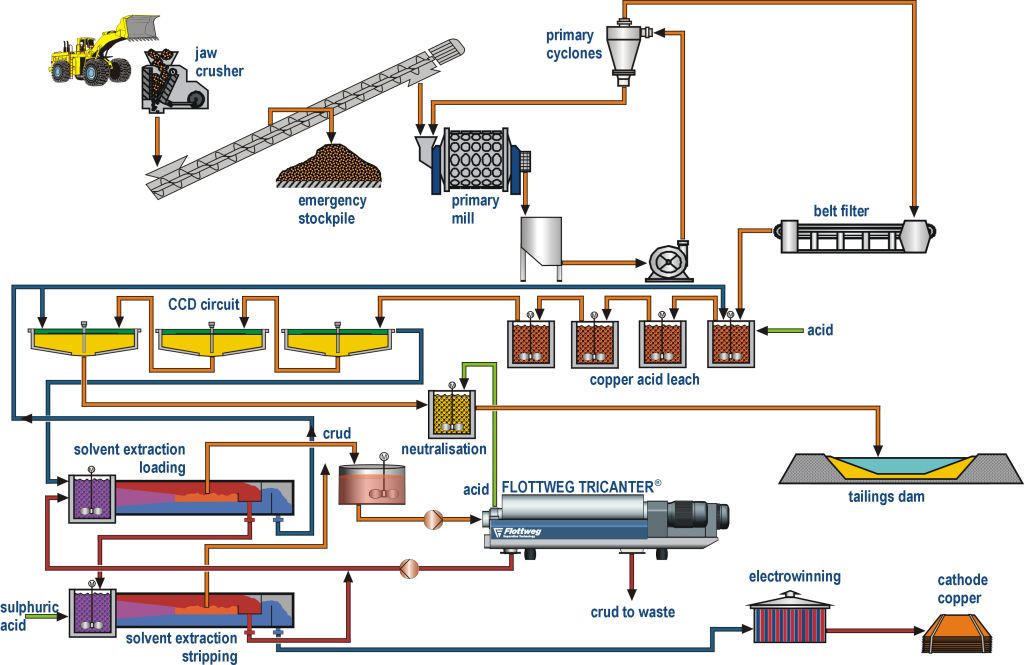

Processing crud for metal extraction with the Flottweg Tricanter®

Extracting metals such as nickel, copper and zinc by liquid extraction with acids is a common procedure. It gives rise to what are referred to as crud layers („chalk river unidentified deposits“). Crud contains a finely distributed solids, organic impurities, air inclusions, gypsum or insects, and is a continuous problem because it reduces the efficiency of the entire process. The solution to this problem is the Flottweg Tricanter®.

Traditional processing systems for crud separation result in very high losses of solvents and elevated operating costs. In the case of copper, for example, the solvent loss is between 2 and 10 kg per tonne of copper produced.

The Tricanter® can divide crud up into its constituents in one working step: aqueous phase, solvent phase and solid. The solvents are recovered directly for reuse in the heavy substance settlers, while the solids are removed for further disposal.

Your advantages in crud processing with the Flottweg Tricanter®

- The Tricanter® reduces solvent losses by up to 50%

- The adjustable impeller of the centrifuge makes it possible to skim off the aqueous phase precisely. The ultrafine solid is output via the scroll.

- Maximum solvent recovery

- Return on investment within one year

- Low working costs due to automatic operation