Recycling Of Brewer’s Grains And Spent Grains

Not every brewery is capable of recycling its brewer’s grains by means of a biogas system. Controlling the fermentation process is complicated, and this process can only be accelerated to a limited extent. Also, it is not always possible to sell the brewer’s grains as animal feed.

The alternative: Mechanical dewatering of the brewer’s grains for optimum recycling. The Flottweg belt press dewaters the brewer’s grains directly from the spent hops storage silo. This can be subsequently incinerated by biomass firing. 1 tonne of wet brewer’s grains contains approx. 1 MWh of thermal energy. Up to 70 – 75% of this can be exploited, depending on the combustion technology used.

Summary: Thermal recycling of brewer’s grains as an environmentally friendly energy source!

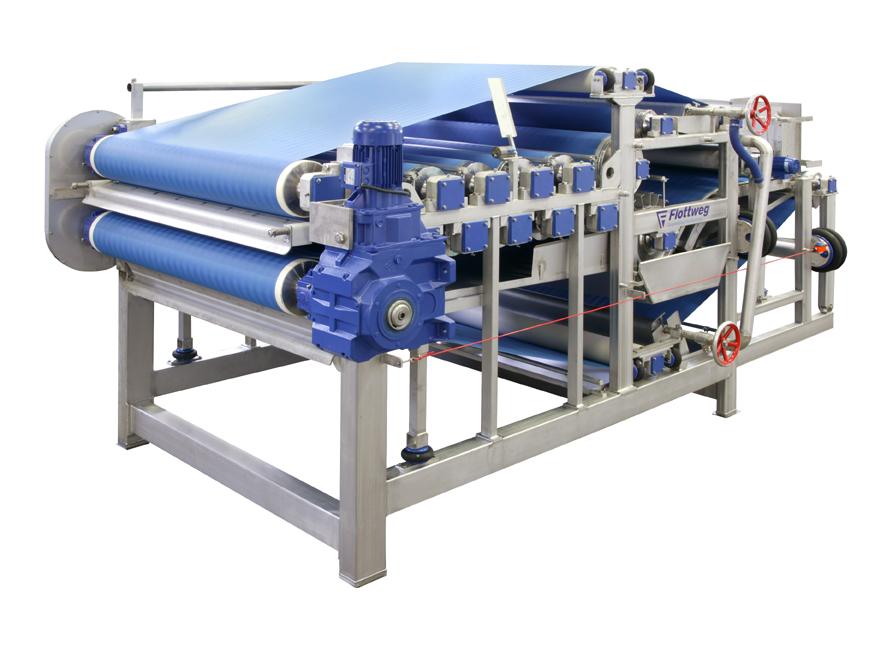

The Flottweg belt press – especially for mechanical dewatering of brewer’s grains

Flottweg adapts the belt press especially for the exacting requirements of dewatering brewer’s grains. The wet brewer’s grains are continuously transported to the belt press.

The high compressive and shearing forces within the machine ensure that an optimum dry matter content of the brewer’s grains is achieved. Prepared in this way, the brewer’s grains can be efficiently used as fuel in biomass firing.

Compared to thermal pre-drying, mechanical dewatering is many times more effective in terms of energy. Each additional percent of dry matter content increases the overall efficiency of energy production by a disproportionate extent. This increases the overall efficiency of the brewing process significantly. Use of the Flottweg belt press represents an environmentally friendly means of generating energy at a highly efficient level.

Advantages of the Flottweg belt press for mechanical dewatering of brewer’s grains:

- CO2-neutral energy generation by recycling renewable raw materials

- High yield of thermal energy contained in the brewer‘ grains

- Guaranteed recycling of the brewer’s grains – independent from external purchasers

- Reduction in the consumption of external energy sources by up to 90%

- Additional incineration of other residues (e.g. old labels) is possible

- Recycling of the press water