PVC And Polyethylen Recycling Using The Industrial Centrifuge

PVC is a thermoplastic polymer which is normally processed in the temperature range from 160 to 200 degrees Celsius. About 34 million tonnes of PVC are manufactured annually worldwide. Compared to other plastics, PVC is inexpensive, easy to manufacture and can be processed in many different ways. Important applications for PVC include the building industry, the electrical industry and the automotive industry.

The decanter for dewatering PVC

Polyvinyl chloride is produced by the polymerisation of vinyl chloride monomer (VCM). There are three manufacturing processes:

- The suspension process

- The microsuspension process

- The emulsion process

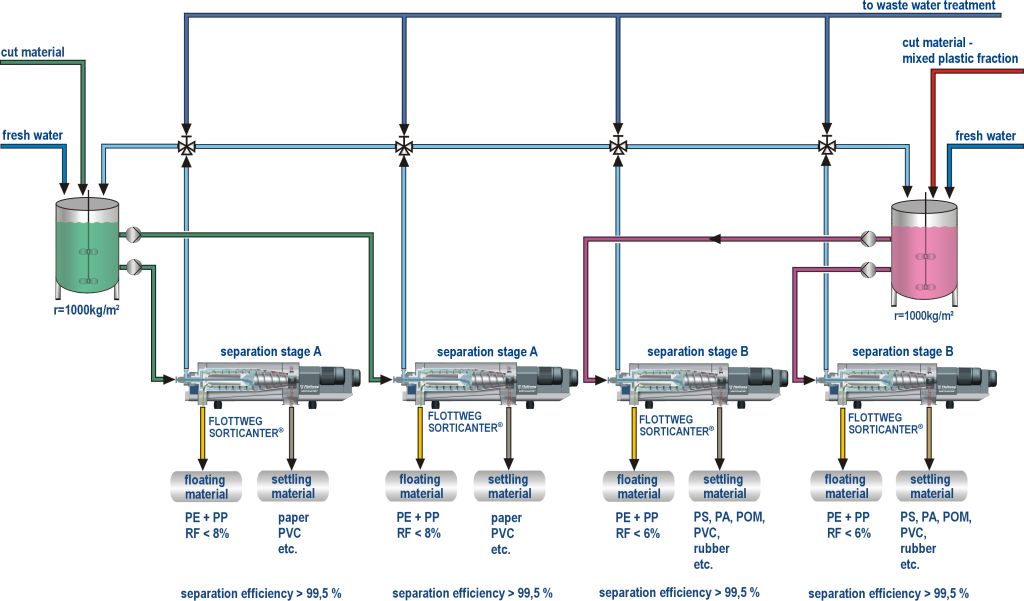

The majority of PVC is manufactured using the suspension process. In the suspension process, decanters are used for dewatering the PVC suspension following polymerisation.

PVC dewatered using the Flottweg decanter has a lower residual moisture level, which means it saves costs during subsequent thermal drying.

Flottweg – your partner for PVC dewatering

Flottweg already has decades of experience with dewatering PVC using centrifuges:

- Flottweg decanters for dewatering PVC are characterised by their extremely robust design

- Flottweg is certified to ISO 9001 and builds its decanter centrifuges according to the latest technical standards – Made in Germany

- By using the decanter, you save cash which would otherwise be spent in thermal drying

- Flottweg is at your disposal 24 hours a day for global spare parts deliveries. Always close to the customer and with a personal service.

- In addition, our decanters are characterised by their high availability