The Centrifuge for Processing of Limed Fleshing in Tanneries

Limed fleshings is a byproduct from tanneries. Valuable animal fat can be recovered during the processing of limed fleshings. Our customers profit twice over from this fat recovery: Firstly, the disposal costs are drastically reduced and, secondly, a valuable raw material is obtained – the fat.

Increasing fuel costs are making fat recovery in tanneries increasingly attractive. The recovered fat can also be used for firing the boiler used for generating the steam.

Flottweg centrifuges are used in tanneries in the following applications:

- Processing limed fleshings

- Recovering animal fats

- Processing wastewater in tanneries

- Processing tannery waste

Flottweg – your partner for processing limed fleshings for recovering animal fats

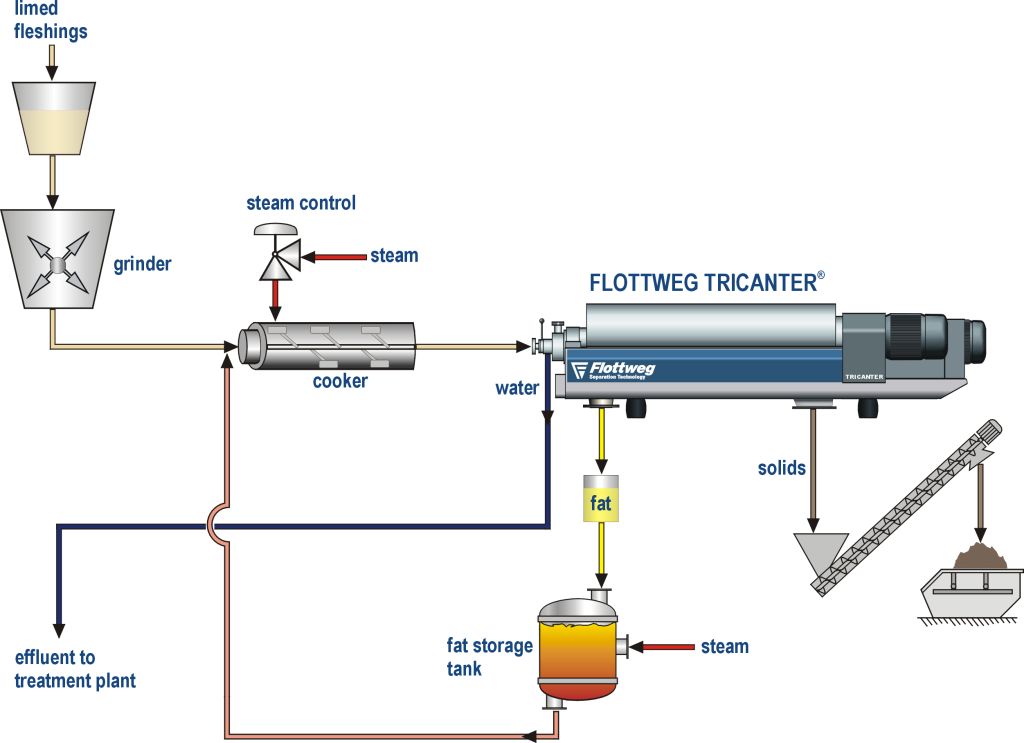

More than twenty years ago, Flottweg carried out the first tests into processing limed fleshings for recovering animal fats with the Tricanter®. Since then, a reliable, efficient and successful process has been developed. In this way, it was possible to reduce disposal costs at the same time as profiting from the fat recovery.

Advantages of the Flottweg Tricanter® when processing limed fleshings in tanneries:

- Drastic reduction in disposal costs – only a fraction of the original waste remains to be disposed of

- Recovering valuable animal fat

- Maximum flexibility by customer-oriented solutions

- Reduction in process costs by fully automatic operation

- Delivery of complete process lines and machines

- Reduction in equipment costs

Flottweg produces all its centrifuges with specialists in Germany. We find the optimum solution for our customers in processing limed fleshings in tanneries. From individual centrifuges through to entire systems – our projects are individually tailored to customers‘ requirements.