Sorticanter®: The Recycling Decanter By Flottweg

Recycling

Environmental protection and recycling are ever greater concerns for companies. As a result, there is a need for new and innovative solutions. This prompted Flottweg to develop the Sorticanter® for processing plastics.

Naturally occurring raw materials such as plants, coal, natural gas and crude oil form the basis for manufacturing plastic. These raw materials cannot be recovered by the chemical steps involved in processing. As a result, recycling plastic is an issue for anyone who is aware of environmental issues. The Sorticanter® makes it possible to contribute to environmental protection according to ecological and economic principles.

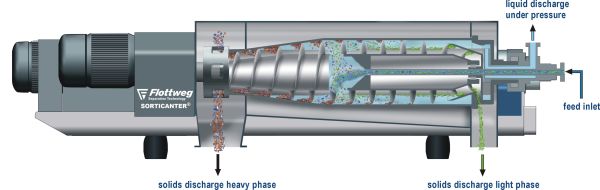

With the centrifugal force that it generates, the Sorticanter® is able to separate different types of plastic from one another. This means operators can obtain the greatest possible purity of plastic grades. Furthermore, collecting and reprocessing plastics cuts disposal costs and reduces the amount of waste.

Turning waste into recyclable material – processing plastics

Having materials of a single type is of central importance when it comes to processing plastics (waste, plastic fibres and lightweight packaging). Many plastics differ from one another in density, as a result of which the sink/swim separation process proves to be the most efficient solution for recycling. In this separation process, a separation liquid is used which has a specific weight between those of the types of plastic to be separated. As a result, the „heavy“ plastic sinks (higher density) to the bottom of a container. The „lighter“ plastic (lower density) floats at the surface of the container. The separation process in a container takes place simply using the force of gravity.

In a centrifuge, gravity is replaced by centrifugal force, which has a positive effect on the separation process (more efficient separation process because the forces acting are many times higher than the force of gravity). The „heavy“ and „light“ plastics are significantly dryer in a centrifuge than in a container. Furthermore, influencing factors such as air bubbles or dust on the surface of the plastics do not affect the separation process in a centrifuge.

Sorticanter® – typical applications

- Processing foils and DSD mixed plastics from packaging materials separated into bags by the general public

- Recycling technical plastics

- Recycling cable sheaths

- Recycling carpet fibres

Sorticanter® – advantages and customer benefits

- Reduced odour because of a closed system

- No influence due to the colour of the solids to be sorted

- Low thermal energy consumption because the dewatering stage (mechanical dewatering) is already integrated in a Sorticanter®

- Sorticanter® is available as a supplement to the existing system (achieving higher yields, because better purity of grades is achieved)

- Better product quality, meaning higher value in the end product

- Minimum personnel costs, making for cost savings by the operator

- Operating times of more than 8000 hours per year are the norm

- Separation of mixed substances that are unsuitable for static separation (fibres)

- No mechanical dryers (screen centrifuges) required

- Processing of particles smaller than 1 mm

- No blow-in of air bubbles or other disruptive effects

- A low-volume closed circuit reduces fresh water consumption

- High availability and minimum wastewater volume, because the majority of contamination is separated out in the Sorticanter®

Flottweg – your expert partner

Since 1995, Flottweg Sorticanter® machines have been processing all kinds of plastics. Numerous respected reference companies all over the world confirm our skills and make us one of the best possible addresses for mechanical separation technology. The Sorticanter® delivers convincing performance and impresses with its outstanding quality and durability. With a Sorticanter®, it is possible to process up to 1000 or 2500 kg of solid per hours (depending on the composition of the raw materials).

Tailor-made systems and extensive expertise make us your ideal partner for your needs and requirements. Contact our experts for advice and benefit from our knowledge.