The Flottweg C Series

The decanter centrifuge for wastewater and sewage sludge

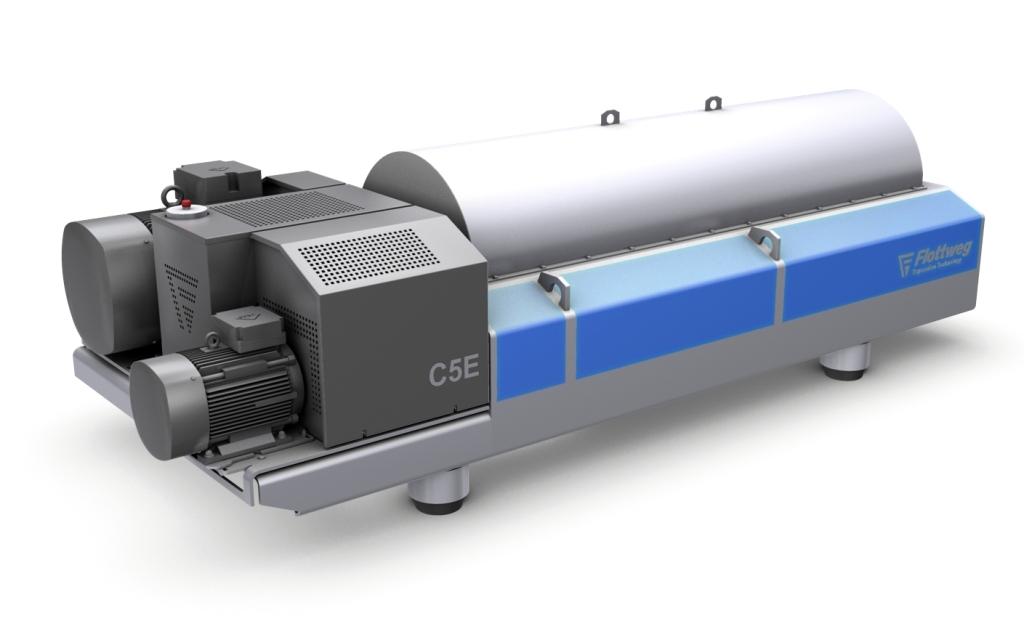

Flottweg decanter centrifuges for wastewater and sewage sludge

Requirements for the quality and efficiency of sewage treatment plants increase year after year, driven not least by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater the incoming sludge. The high-performance centrifuges of the Flottweg C series achieve the best possible values for total dry solids in the sludge.

By combining an energy-efficient, powerful drive, the Flottweg Simp Drive®, with a continuously optimized decanter geometry, Flottweg decanter centrifuges achieve values several percentage points above those of other models. The right machine is available for any size system. The continuous further development of Flottweg decanter centrifuges guarantees not only user-friendly control, but also optimum sludge thickening (the OSE) and the best possible sludge dewatering (HTS). Flottweg has developed the C series especially for this purpose in order to meet the requirements of the wastewater market explicitly. These decanter centrifuges have a power argument in the unit count of over 350 successfully working machines.

The Flottweg C series

Full power despite reduced energy requirements

Energy savings in wastewater treatment, up to and including energy-autonomous sewage treatment plants, are no longer just nice to have but actually a part of the community environmental movement. This movement also includes dewatering technology, which has its part to play. The Flottweg C series accelerates the incoming separation medium in a particularly advantageous manner. Thanks to the combination of a large and geometrically optimized sludge discharge, power consumption can be reduced by up to 30 percent. Our customers also have the option of using the Flottweg Recuvane® System. In all, you can achieve energy savings of up to 50 percent! That’s as sustainable as it gets.

The Flottweg Recuvane® System

Choose the lowest energy consumption

The lion’s share of electric power is required to accelerate the separation medium. After separation, the liquid (centrate) exits the system, leaving the rotational energy unused. The Flottweg Recuvane® System allows customers to recover part of that rotational energy. A carefully designed centrate discharge supports the main drive, leading directly to a reduction in electrical power consumption of about 20 percent. The greatest possible efficiency = great customer satisfaction.

Flottweg decanter centrifuges

Performance and reliability of the Flottweg C series

The Flottweg C series is a high-performance centrifuge for sludge dewatering with the best possible total dry solids values. For example, by increasing total dry solid content from 23 percent to 25 percent, Flottweg customers can reduce sludge volume by eight percent. As a result, transport and disposal costs also fall by eight percent. That savings potential means that an investment in the latest dewatering technology from Flottweg can be amortized over a very short time. The best possible quality and the greatest possible reliability also permit the operation of Flottweg decanter centrifuges for 20 years or more.

Choose the high-performance centrifuges in the Flottweg C series and take advantage of ongoing savings in transport and disposal costs.

The Flottweg Simp Drive®

Automatic regulation and full torque

The Simp Drive® regulates the differential speed between the decanter bowl and the decanter scroll depending on the scroll torque. This is done during ongoing operation. The bowl and scroll are completely independent of one another. The Flottweg Simp Drive® provides the full torque both with the bowl at rest and at maximum speed. During ongoing operation, any change in feed rate is detected by automatic torque regulation. This permits Flottweg to ensure the best possible quality of the solids discharged, since the system always reacts to changing product characteristics in the feed.

The Flottweg wastewater decanters – advantages over other processes and competitors‘ machines

- No health risk for system personnel (no aerosol pollution and no escaping contamination or odors due to closed system)

- Continuously provides the best possible separation results due to its automatic and independent regulation of the bowl and differential speeds (Simp Drive®)

- Minimum downtime thanks to the maintenance-friendly, easy-access design of the C series

- Greater sedimentation volumes (due to the deep pond and steep cone) permits a higher power density (by 10 – 20 percent) in less space

- Reduced energy consumption by up to 30 percent due to large, geometrically optimized sludge discharge

- Reduction in operating costs due to reduced flocculant consumption

- Energy savings of about 20 percent using the Flottweg Recuvane® System

- Minimal supervision needed, even including automated 24/7 operation

- Highest possible service life due to the use of high-quality stainless steel (rust- and acid-resistant) and an optimized wear protection package

The wastewater decanters of the Flottweg C series

Decades of experience in sewage sludge and wastewater make Flottweg one of the leading providers of mechanical separation technology. We meet the special requirements of sewage treatment plants and water management in terms of dewatering performance, cost-effectiveness, and user-friendliness. Well-known and especially satisfied customers around the world can confirm that. The Flottweg decanters in the C series are attractive for their cost-effectiveness, performance, and long service life. The right machine is available for any size system.

We can offer you comprehensive know-how and customized systems. Our experts would be happy to talk to you.