The Flottweg Belt Press

Applications for Flottweg belt presses

The Flottweg belt press is suitable for various applications in mechanical separation technology:

- Juice manufacture: Fruit juice (direct juice), concentrate and vegetable juice

- Dewatering of brewer’s grains

- Algae extract

- Coffee grounds

- Herb extracts

- Soya

- Starch

- Additional applications in the areas of foodstuffs, chemicals and pharmaceuticals

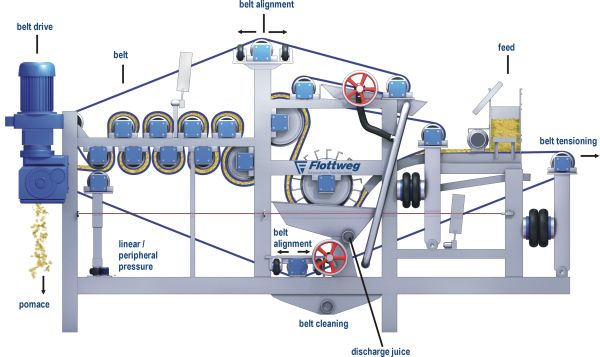

Mode of function of the Flottweg belt press

The pulp is continuously and evenly spread over the bottom belt. Then the top belt is guided onto the product. This ensures that the surface pressure increases evenly, and that a stable pulp product cake is formed.

In the press area, dewatering takes place via an L-profiled roller which ensures the liquid flows out quickly. Following this, the pulp is pressed out via press rollers with reducing roller diameters. The increasing pressure load extracts the juice from the pulp optimally and quickly.

Optional linear press rollers and edge zone pressure rollers increase the effectiveness of the belt press further. In this way, a juice yield in excess of 90% can be achieved in 2-stage operation. For stable continuous operation, high-pressure nozzles clean both belts continuously after the pomace has been removed.

Advantages of the Flottweg belt press

- Continuous and reliable operating method with minimum operating complexity

- Consistent use of stainless steel for a high hygienic standard

- Very good resilience and durability

- Clear design and easy access for cleaning, operation and maintenance

- Efficiency and very good yield

- Automatic belt control for optimum tension and guidance of the belts